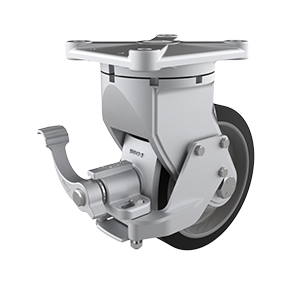

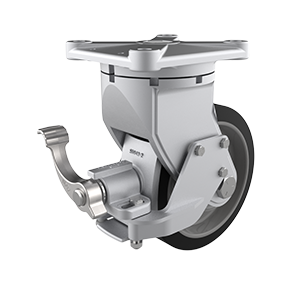

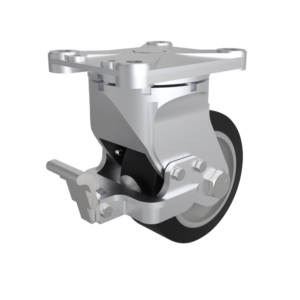

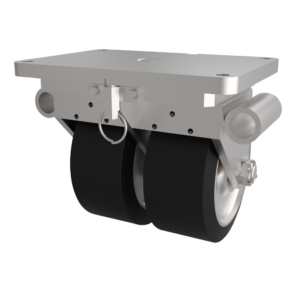

Aluminum Casters

Aerol Aluminum casters have been known throughout the world for their durability and low maintenance costs. To maintain the level of performance, the manufacturers of components for Aerol Casters and wheels are continuously upgraded. Because of this standard in high quality and performance satisfaction, every major industry and all branches of the Armed Forces are using Aerol products in hundreds of applications.

In order to produce superior wheels and casters, Aerol Engineers and Metallurgists selected aluminum as the most suitable material because of its high corrosion resistance, its high tensile strength, and its uniform sectional properties. The adaptability of aluminum to permanent mold casting provides the ultimate in modern materials handling media.

The universal acceptance of Aerol wheels and casters for high-performance environments supports the choice of aluminum as the base material with which to produce the finest caster and wheel combinations available today.

Application

If your caster application requires:

- High corrosion resistance to moisture, detergents in normal solution, abrasives, brine, food products, or foreign matter.

- Spark Proofing

- Or Minimum Weight, an Aluminum Maintenance-free Aerol Caster is your answer.

Custom CAD

Options

Aerol has a wide variety of caster options. Many of these not only improve function – but also provide safety and add longevity to the product. When considering safety options, the most common consideration would be caster swivel locks, floor locks, and aluminum or steel pedal foot brakes.

Other options include clean room certified casters that do not emit gasses, are non-marking, and sealed so grease will not leak out, In addition, non-magnetic and spark proof casters are ideal for companies that make black powder, explosives, or fireworks.